The job of loading baggage on airplanes is hard, but it doesn’t have to be injurious to the men and women who do the job.

In Sitka, a baggage handler — or “ramper,” as they’re known in the airline business — has designed and built a piece of equipment he hopes revolutionizes the way commercial aircraft are loaded, sparing rampers like himself a lot of physical aches and pains.

As part of the CoastAlaska series “Alaska Made,” a Sitka aviation entrepreneur behind Ramper Innovations.

On an overcast summer day, ramper Tim Fulton waits for the arrival of Alaska Airlines Flight 53 at the Sitka Rocky Gutierrez Airport.

Flight 53 circles low over Sitka Sound and touches down, trailing ribbons of mist from its wingtips. The Boeing 737-800 pulls up to the gate, and Fulton and his coworker, Craig Langefield, climb up the belt loader into the belly of the beast.

Watching rampers work brings to mind country singer Dave Carroll’s YouTube video, “United Breaks Guitars.” Carroll penned the song after United Airlines refused to compensate him for the damage incurred by his guitar while in transit. After the video went viral, United offered Carroll flight vouchers, but he declined to accept them.

But to a ramper, your bag — your clothing, your fish, your tools, or even your Taylor guitar — is just weight. Weight that has to be pushed (or tossed) and stacked onto a pile that begins far from the doorway — by two people working on their knees.

Flight 53 carries a relatively light load in the aft belly: only 2,300 pounds. There is a lot more at risk here than guitars.

“Forward-bending is challenging on the spine. Twisting is challenging on the spine, and lifting is challenging,” said physical therapist Eric Speck. “When you combine all three you have the perfect storm of forces for the low back.”

Speck has treated a lot of rampers in over two decades at his Sitka practice. He thinks Fulton’s device will be a game-changer for the teams that load airplanes.

“It changes the person who first receives the bag on their knees,” said Speck, “having to accelerate it down the plane, which is a huge twisting moment on the low back, rotating and sending it down the plane. And now he just has to place it there, and the belt is going to take it down. That’s a very big difference.”

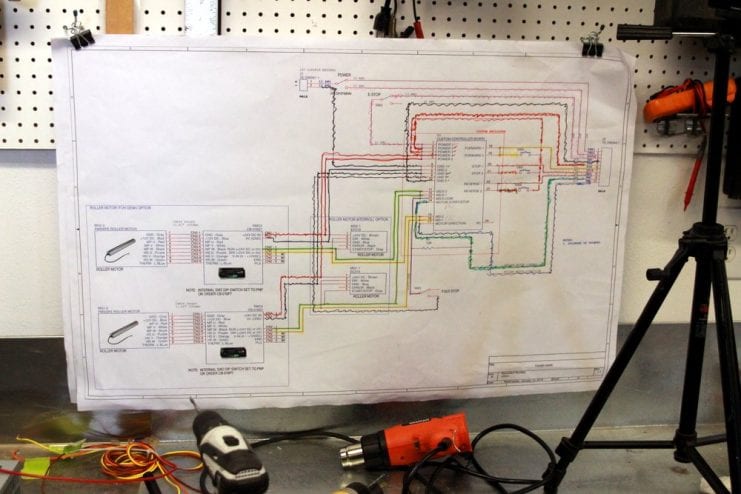

Working out of his garage — a fully-equipped machine shop, actually — Fulton has designed and built “TISABAS,” short for “TIm SAves BAckS.” The invention is a lightweight, collapsible conveyor belt that can take the heaviest bag you could ever pack. To be precise, Fulton said it’s designed to hold 150 pounds per square foot.

A conveyor belt is nothing new, but the TISABAS conveyor folds up in sections — like an accordion — to fit inside a plane’s belly doors. And then it extends or retracts, depending on whether the task is loading or unloading. Each time Fulton lowers one of the sections of TISABAS into position, the belt in that section automatically starts. And when he raises it, the belt stops. A switch reverses the belt’s direction.

Fulton has already built and sold rollers used by Alaska Airlines to load fish boxes into their planes, but regular luggage was a struggle. He said it was like “pushing them on a rutted road.”

“And I got to the point where (there were) probably 20 prototypes into a roller that would do this job, and it just wasn’t meeting the force reduction that I was looking for,” Fulton said. “And that’s when I came up with the idea of a folding belted system.”

Back at the airport, the first full trial of TISABAS has been brilliant. Fulton and Langenfeld turned around luggage in the aft belly just a little faster than their colleagues forward — but Fulton, with two shoulder surgeries and a painful hip, said his back is doing just fine.

But how do the other rampers feel? One ramper who hadn’t seen the trial was concerned that TISABAS — or similar technology — would cost jobs on the ramp, and that airlines might adopt it to cut costs, rather than to save backs. Another third-year ramper, Evan Sutton, was more upbeat. “It went well,” he said. “I felt like they had a good rhythm, and they kept up with the belt (loader). That’s all we really wanted.”

An airline may assign a third person to load in the aft belly of longer aircraft, like the Boeing 737-900, but these rampers say that most of the time there are only two.

Ramper Bob Weaver has suffered injuries to his elbow and shoulder in the past. He sees promise in TISABAS.

“I was impressed. This was the first time I’ve seen it in action, and it worked a lot better than I expected,” Weaver said.

He added that an alternate way to mitigate rampers’ injuries would be for passengers to pack lighter.

“People bring too much stuff,” Weaver said. “You don’t need high heels in Alaska.”

Fulton’s new company, Ramper Innovations, hopes to sell TISABAS for around $40,000 each — about 20 percent of the cost of his closest competitor. Fulton has already begun conversations over possible licensing deals. Ramper Innovations was one of five businesses chosen by the aviation business accelerator AeroInnovate for its Class of 2018.

What happened inside the belly of Flight 53 has been a long time coming.

“Right now, my thought is, ‘I got this,'” Fulton said. “I’ve got the proof of concept. Get some investors, help me take it to the next stage. This one is basically all mine. I know it. I know what has to be fixed. I got this.”

And his distribution plan is simple: He’ll load TISABAS as cargo — collect to airports all over the world — in the belly of planes just like the Boeing 737-900.