Alaska is not known for having much of a manufacturing sector, and at the end of a long supply chain there’s been concern that the state will run out of the medical supplies it needs to fight coronavirus.

But at least two small businesses in Alaska are retooling their operations from making things like custom car or gun parts, to producing face shields for protecting healthcare providers and printing the long swabs needed to test for the virus.

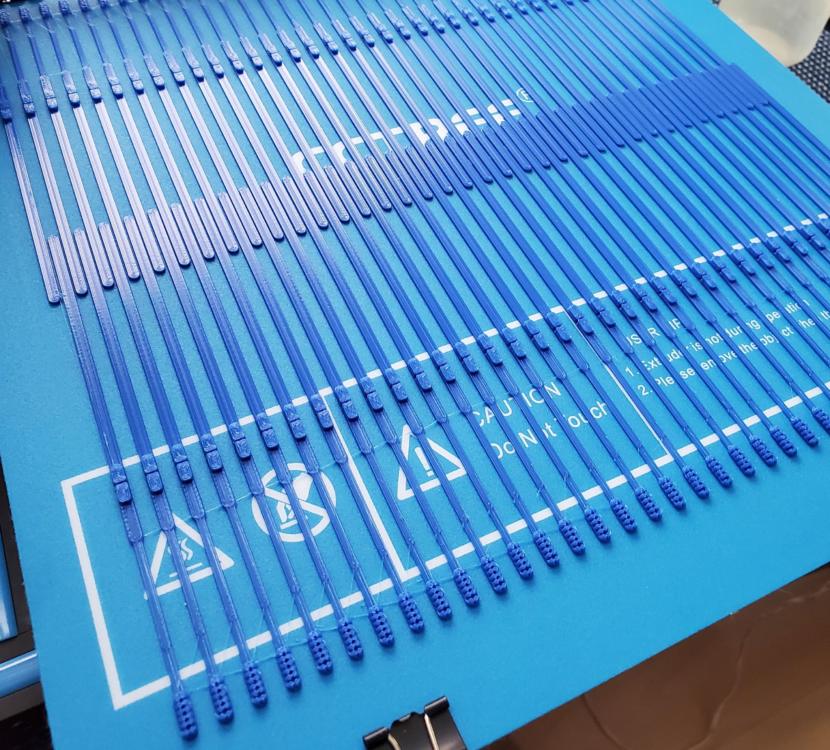

At TriJet Manufacturing in Palmer, a 3D printing machine is constantly whirring, busy printing plastic test swabs. These swabs don’t have cotton tips, more of a scraper on the end, and they’re longer than the swabs you might have in your bathroom. They’re long enough, actually, to reach through a person’s nose all the way to the back of their throat to collect a sample of mucus.

“It’s not that comfy,” said TriJet CEO Hans Vogel. “Honestly, I wasn’t really aware you could stick things to the back of your throat through your nose, but who knows?”

That uncomfortable procedure was unknown to Vogel, because the company’s typical work involves creating, from scratch, everything from custom gun parts and helicopter fuel tanks, to huge steel carts used to move entire turbine engines or pieces of oil drilling pipe.

But now TriJet is starting to crank out thin, blue, plastic test swabs, each one about six inches long, as well as clear plastic face shields for medical workers administering those tests.

Vogel said his company isn’t the only one. He pointed to distilleries around the state switching to making alcohol for hand sanitizer instead of alcohol to drink. In some hard-hit countries, engineers and manufacturers have also reconfigured to meet demand in what has become a life-or-death struggle.

“Instead of watching, you know, silly cat videos at home while you’re stuck in your house, I mean, some of these people are looking at how they can help,” Vogel said. “I think people in all walks of life are doing that. But we just happen to have some of the ingredients necessary, the people and the machines, and so that’s why we’re going after it.”

Here’s how it works: A company like TriJet with an industrial-sized 3D printer can download the digital design for swabs and maybe modify it a little to fit their particular machine’s needs or other technical specifications. They input the design to the printer, punch a couple buttons and it starts printing swabs from a string of plastic filament.

“Like a thick fishing line, and it goes through this thing called an extruder. Just think like a hot glue gun,” Vogel said. “And it just kind of wiggles around. There’s a robot that moves around, as this little noodle of hot plastic is coming out. It’s basically taking that model, and layer by layer, it’s building your part.”

Gov. Mike Dunleavy approached TriJet in mid-March asking if the company could produce swabs and what their capacity might be, Vogel said. As members of the greater design community, his engineers were already thinking about it, he said.

And just Thursday, the state approved TriJet’s first batch of 140 swabs. They’re currently capable of producing a couple hundred a day but could quickly scale up to make hundreds more per day if needed, Vogel said.

For now, the company isn’t seeking compensation for the swabs, though that’s something that could change if they have to hire more workers to increase production, Vogel said.

“We might need some resources, and (if it) starts becoming a big level of effort, we’re going to have to do it. Yeah, clearly, like any normal company at this point, we’re all looking at our own mortality,” Vogel said.

Another Alaska company looking to help is Perfectionist Auto Sound in Anchorage. Company CEO John Schwartz described Perfectionist as a “tailor” for vehicles, modifying suspensions, wheels and tires, installing audio systems, custom interiors and backup cameras.

“We build people’s dreams of what they want their car to be,” Schwartz said.

Now, though, Schwartz is staying busy producing face shields for medical workers.

Schwartz appeared in a video on Perfectionist’s Facebook page, standing next to their busy 3D laser cutter.

“Got the laser going. We’re going to get as many face shields done as we can and get these out in the public,” Schwartz said in the video. “We’re going to start assembling soon.”

The machines are usually busy making things like logos or special brackets for after-market fog lights. But Schwartz said he switched to face shields after a friend in Boston started doing the same thing.

“So this part of it is like my contribution back to the community,” he said. “Because I can be open, I can work, where some people can’t. So at least if I can help people, then I have some purpose to be here.”

Schwartz delivered a load of face shields to Alaska Native Medical Center in Anchorage on Thursday and said he’s made about 200 total, with a goal of 500. A competitor in town even provided more materials to keep going, and he’s also sent the digital design files to other, larger, companies with similar printing and cutting machines, he said.

The work is making him feel useful, Schwartz said, but he’d also like to think it could save lives.

“I have a lot of smaller practices and, you know, people running the testing centers and things like that, that really need them,” Schwartz said. “So we’re just going to keep producing as we can.”